Yamaha YZF-R125 Service Manual: Installing the crankshaft

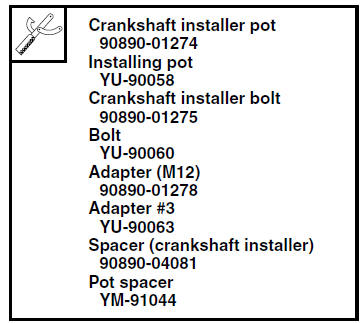

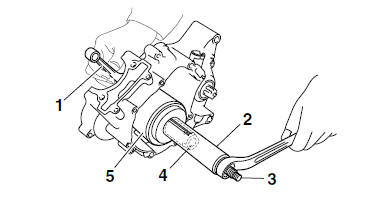

1. Install:

- Crankshaft "1"

NOTE:

Install the crankshaft with the crankshaft installer

pot "2", crankshaft installer bolt "3", adapter

(M12) "4" and spacer (crankshaft installer) "5".

| CAUTION: To avoid scratching the crankshaft and to ease the installation procedure, lubricate the oil seal lips with lithium-soap-based grease and each bearing with engine oil. |

NOTE:

Hold the connecting rod at top dead center (TDC) with one hand while turning the nut of the crankshaft installer bolt with the other. Turn the crankshaft installer bolt until the crankshaft bottoms against the bearing.

Checking the crankshaft

Checking the crankshaft

1. Measure:

Crankshaft runout

Out of specification Replace

the crankshaft,

bearing or both.

NOTE:

Turn the crankshaft slowly.

2. Measure:

Big end side clearance

Out of speci ...

Transmission

Transmission

...

Other materials:

Installing the cylinder head

1. Install:

Cylinder head

NOTE:

Pass the timing chain through the timing chain

cavity.

2. Tighten:

Cylinder head bolts "1"

Cylinder head bolts "2"

NOTE:

Lubricate the cylinder head bolts and washers

with engine oil.

Tighten the cylinder head bolts in the proper

tighten ...

Measuring the compression pressure

NOTE:

Insufficient compression pressure will result in a

loss of performance.

1. Measure:

Valve clearance

Out of specification →Adjust.

Refer to "ADJUSTING THE VALVE CLEARANCE"

on page 3-3.

2. Start the engine, warm it up for several minutes,

and then turn it off.

3. Remove:

...

Installing the exhaust assembly

1. Install:

Exhaust assembly "1"

Exhaust pipe nuts "2"

Exhaust assembly bolts "3" "4"

NOTE:

Do not fully tighten the nuts and bolts.

2. Tighten:

Exhaust pipe nuts "2"

Exhaust assembly bolt "4"

Exhaust assembly bolt "3"

...