Yamaha YZF-R125 Service Manual: Checking the lean angle sensor

1. Remove:

- Lean angle sensor

2. Check:

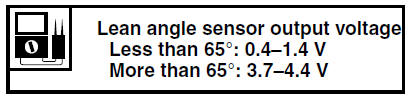

Lean angle sensor output voltage

Out of specification  Replace.

Replace.

a. Connect the lean angle sensor to the wire harness.

b. Connect the pocket tester (DC 20 V) to the

lean angle sensor coupler as shown.

Positive tester probe

yellow/green "1"

Negative tester probe

gray/black "2"

c. Set the main switch to "ON".

d. Tilt the lean angle sensor to 65.

e. Measure the lean angle sensor output voltage.

Checking the crankshaft position sensor

Checking the crankshaft position sensor

1. Disconnect:

Crankshaft position sensor coupler

(from the wire harness)

2. Check:

Crankshaft position sensor resistance

Out of specification Replace

the crankshaft

position senso ...

Checking the starter motor operation

Checking the starter motor operation

1. Check:

Starter motor operation

Does not operate → Perform the electric

starting system troubleshooting, starting with

step 4.

Refer to "TROUBLESHOOTING" on page

8-9.

a. Con ...

Other materials:

Disassembling the water pump

1. Remove:

Water pump seal "1"

NOTE:

Remove the water pump seal from the inside of

the water pump housing "2".

2. Remove:

Bearing "1"

NOTE:

Remove the bearing from the outside of the water

pump housing "2".

...

Checking the friction plates

The following procedure applies to all of the friction

plates.

1. Check:

Friction plate

Damage/wear Replace the

friction plates

as a set.

2. Measure:

Friction plate thickness

Out of specification Replace

the friction

plates as a set.

NOTE:

Measure the friction plate ...

Troubleshooting method

The engine operation is not normal and the

engine trouble warning light comes on.

1. Check:

Fault code number

a. Check the fault code number displayed on

the FI diagnostic tool.

b. Identify the faulty system with the fault code.

Refer to "Self-Diagnostic Function table".

c. Identi ...