Yamaha YZF-R125 Service Manual: Checking the fuses

The following procedure applies to all of the fuses.

| CAUTION: To avoid a short circuit, always turn the main switch to "OFF" when checking or replacing a fuse. |

1. Remove:

- Rider seat Refer to "GENERAL CHASSIS" on page 4-1.

2. Check:

- Fuse

a. Connect the pocket tester to the fuse and check the continuity.

Set the pocket tester selector to "

× 1".

× 1".

b. If the pocket tester indicates " ", replace the fuse.

3. Replace:

- Blown fuse

a. Set the main switch to "OFF".

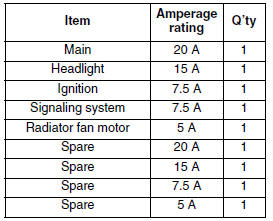

b. Install a new fuse of the correct amperage rating.

c. Set on the switches to verify if the electrical circuit is operational.

d. If the fuse immediately blows again, check

the electrical circuit

| WARNING Never use a fuse with an amperage rating other than that specified. Improvising or using a fuse with the wrong amperage rating may cause extensive damage to the electrical system, cause the lighting and ignition systems to malfunction and could possibly cause a fire. |

4. Install:

- Rider seat Refer to "GENERAL CHASSIS" on page 4-1.

Checking the condition of the bulb sockets

Checking the condition of the bulb sockets

The following procedure applies to all of the bulb

sockets.

1. Check:

Bulb socket (for continuity)

(with the pocket tester)

No continuity Replace.

NOTE:

Check each bulb socket for continui ...

Checking and charging the battery

Checking and charging the battery

WARNINGBatteries generate explosive hydrogen gas

and contain electrolyte which is made of poisonous

and highly caustic sulfuric acid.

Therefore, always follow these preventive

mea ...

Other materials:

Checking the horn

1. Check:

Horn resistance

Out of specification Replace.

a. Disconnect the horn connectors from the

horn terminals.

b. Connect the pocket tester ( × 1) to the horn

terminals.

Positive tester probe

horn terminal "1"

Negative tester probe

horn terminal "2"

c. Measure t ...

Checking the rear shock absorber assembly

1. Check:

Rear shock absorber rod

Bends/damage Replace the rear

shock

absorber assembly.

Rear shock absorber

Oil leaks Replace the rear

shock absorber

assembly.

Spring

Damage/wear Replace the

rear shock absorber

assembly.

Bushing

Damage/wear Replace the rea ...

Assembling the front fork legs

The following procedure applies to both of the

front fork legs.

WARNING

Make sure the oil levels in both front fork

legs are equal.

Uneven oil levels can result in poor handling

and a loss of stability.

NOTE:

When assembling the front fork leg, be sure to

rep ...