Yamaha YZF-R125 Service Manual: Installing the clutch

1. Install:

- Conical spring washer "1"

NOTE:

Install the conical spring washer as shown in the illustration.

2. Install:

- Clutch housing

- Thrust washer "1"

NOTE:

Be sure to install the thrust washer so that its sharp edge "a" is facing away from the clutch boss.

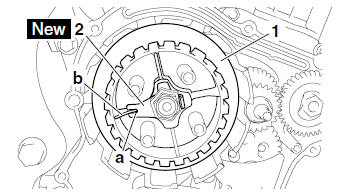

3. Install:

- Clutch boss "1"

- Lock washer "2"

- Clutch boss nut

NOTE:

- Lubricate the clutch boss nut threads and lock washer mating surfaces with engine oil.

- Align the notch "a" in the lock washer with a rib "b" on the clutch boss.

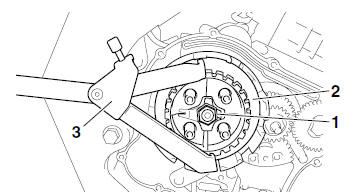

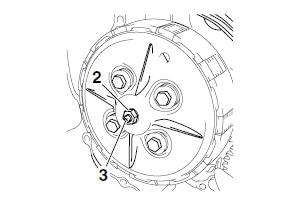

4. Tighten:

- Clutch boss nut "1"

NOTE:

While holding the clutch boss "2" with the universal

clutch holder "3", tighten the clutch boss nut.

5. Bend the lock washer tab along a flat side of the nut.

6. Lubricate:

- Friction plates

- Clutch plates

(with the recommended lubricant)

7. Install:

- Clutch damper spring seat "1"

- Clutch damper spring "2"

- Friction plate 2

- Clutch plates

- Friction plates 3

- Friction plate 1

NOTE:

- Install the clutch damper spring seat and clutch damper spring as shown in the illustration.

- First, install a friction plate and then alternate between a clutch plate and a friction plate.

8. Install:

- Pressure plate

- Clutch springs

- Clutch spring bolts "1"

NOTE:

Tighten the clutch spring bolts in stages and in a crisscross pattern.

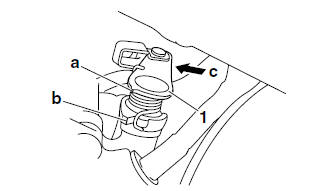

9. Adjust:

- Clutch mechanism free play

a. Check that projection "a" on the clutch push lever "1" aligns with mark "b" shown on the crankcase in the illustration by pushing the clutch push lever manually in direction "c" until it stops.

b. If projection "a" is not aligned with mark "b", align them as follows:

- Loosen the locknut "2".

- With the clutch push lever fully pushed in direction "c", turn the short clutch push rod "3" in or out until projection "a" aligns with mark "b".

- Hold the short clutch push rod to prevent it

from moving and then tighten the locknut to

specification.

10.Install:

- Oil seal "1"

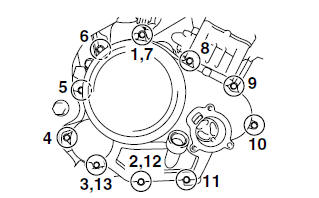

11.Install:

- Clutch cover

NOTE:

Tighten the clutch cover bolts in the proper tightening sequence as shown.

12.Adjust:

- Clutch cable free play Refer to "ADJUSTING THE CLUTCH CABLE FREE PLAY" on page 3-12.

Checking the primary driven gear

Checking the primary driven gear

1. Check:

Primary driven gear "1"

Damage/wear Replace the

primary drive

gear and clutch housing as a set.

Excessive noise during operation

Replace

the primary drive gear and ...

Oil pump

Oil pump

...

Other materials:

Adjusting the engine idling speed

The engine idling speed must be

checked and, if necessary, adjusted as

follows at the intervals specified in the

periodic maintenance and lubrication

chart.

The engine should be warm before

making this adjustment.

Remove panel A.

Check the engine idling speed

and, if necessary, ...

Coolant

The coolant level should be checked

before each ride. In addition, the coolant

must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

To check the coolant level

Place the vehicle on a level surface

and hold it in an upright position.

TIP

...

Types of bulbs

The bulbs used on this vehicle are shown in the

illustration.

Bulbs "a" and "b" are used for the headlights

and usually use a bulb holder that must be detached

before removing the bulb. The majority

of these types of bulbs can be removed from

their respective socket by turning them coun ...