Yamaha YZF-R125 Service Manual: Adjusting the drive chain slack

NOTE:

The drive chain slack must be checked at the tightest point on the chain.

| CAUTION: A drive chain that is too tight will overload the engine and other vital parts, and one that is too loose can skip and damage the swingarm or cause an accident. Therefore, keep the drive chain slack within the specified limits. |

1. Stand the vehicle on a level surface.

| WARNING Securely support the vehicle so that there is no danger of it falling over. |

NOTE:

Both wheels should be on the ground without a rider on the vehicle.

2. Turn the rear wheel several times and find the tightest position on the drive chain.

3. Check:

- Drive chain slack "a"

Out of specification

Adjust.

Adjust.

NOTE:

Measure the drive chain slack halfway between the drive axle and the rear wheel axle.

4. Adjust:

- Drive chain slack

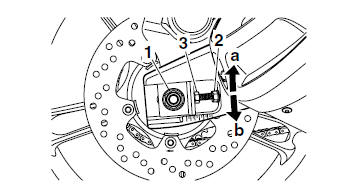

a. Loosen the wheel axle nut "1".

b. Loosen both locknuts "2".

c. Turn both adjusting bolts "3" in direction "a" or

"b" until the specified drive chain slack is obtained.

NOTE:

- To maintain the proper wheel alignment, adjust both sides evenly

- Push the rear wheel forward to make sure there is no clearance between the drive chain pullers and the ends of the adjusting bolts.

d. Tighten the wheel axle nut to specification.

e. Tighten the locknuts to specification.

Bleeding the hydraulic brake system

Bleeding the hydraulic brake system

WARNINGBleed the hydraulic brake system whenever:

the system is disassembled.

a brake hose is loosened, disconnected or

replaced.

the brake fluid level is very low.

brak ...

Lubricating the drive chain

Lubricating the drive chain

The drive chain consists of many interacting

parts. If the drive chain is not maintained properly,

it will wear out quickly. Therefore, the drive

chain should be serviced, especially when the

vehi ...

Other materials:

Checking the timing chain tensioner

1. Check:

Timing chain tensioner

Cracks/damage/rough movement Replace.

a. Lightly press the timing chain tensioner rod

into the timing chain tensioner housing by

hand.

NOTE:

While pressing the timing chain tensioner rod,

wind it clockwise with a thin screwdriver "1" until

it stops.

b. ...

Checking the rectifier/regulator

1. Check:

Rectifier/regulator output voltage

Out of specification → Replace the

rectifier/

regulator.

a. Set the engine tachometer to the spark plug

lead.

b. Connect the pocket tester (DC 20 V) to the

rectifier/regulator coupler as shown.

Positive tester probe

red "1"

Negat ...

Installing the fuel hose

1. Install:

Fuel hose

Fuel hose connector cover

CAUTION:When installing the fuel hose, make sure

that

it is securely connected, and that the fuel

hose connector cover is in the correct position,

otherwise the fuel hose will not be properly

installed.

NOTE:

W ...