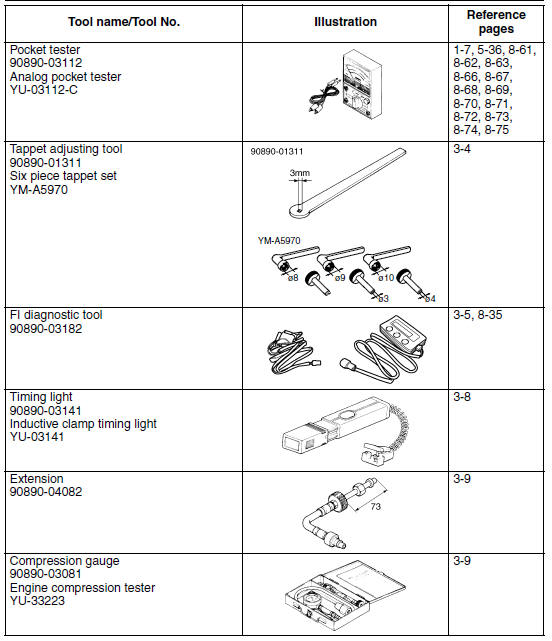

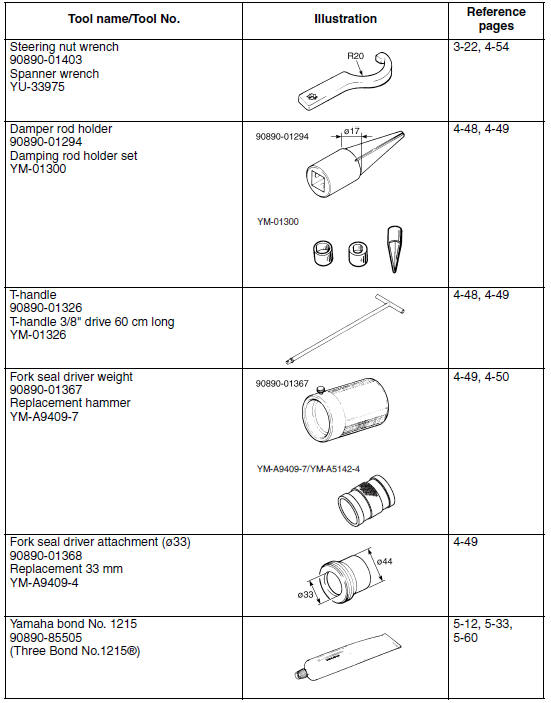

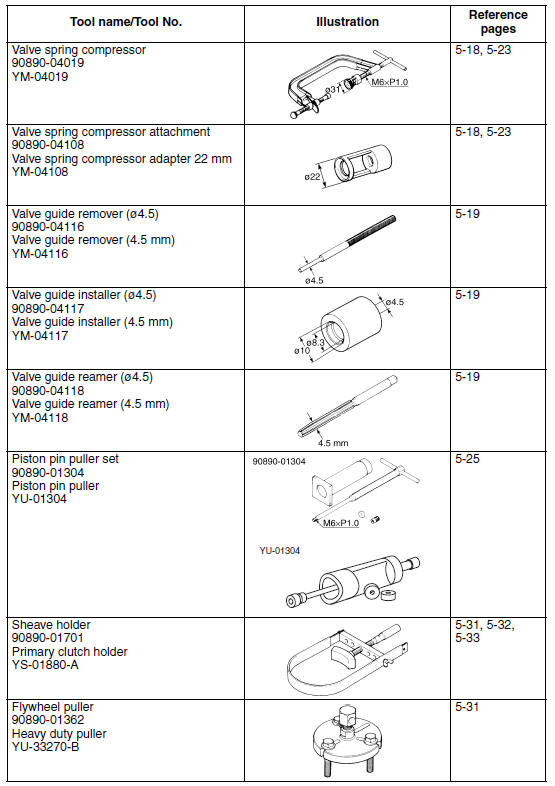

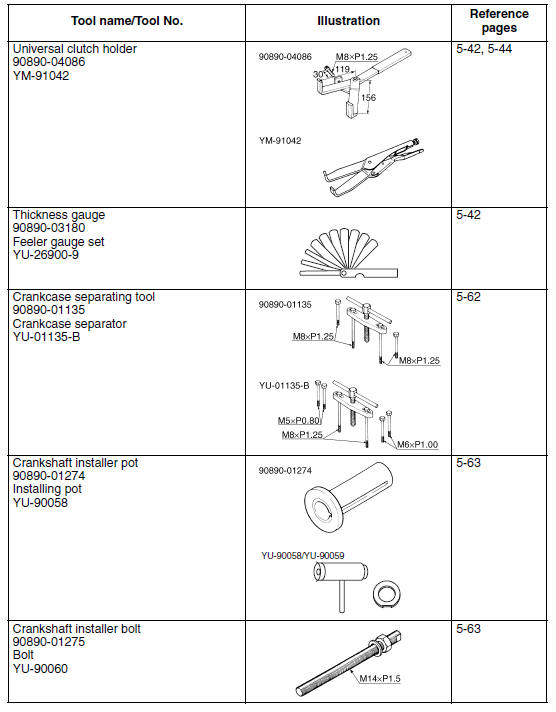

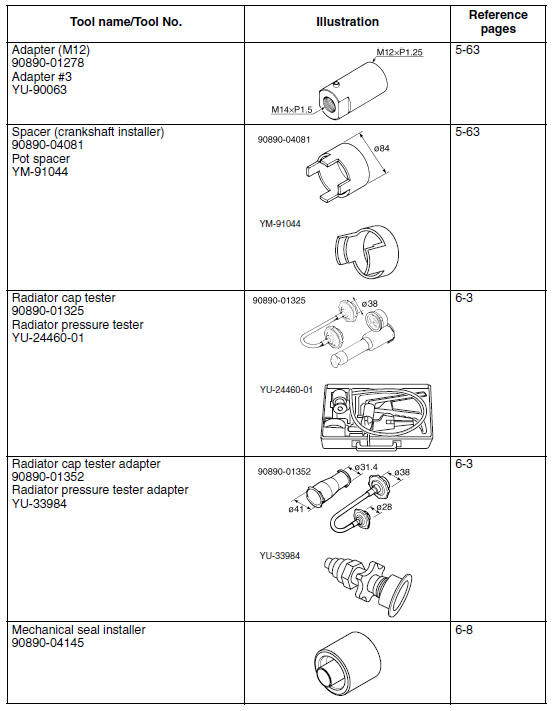

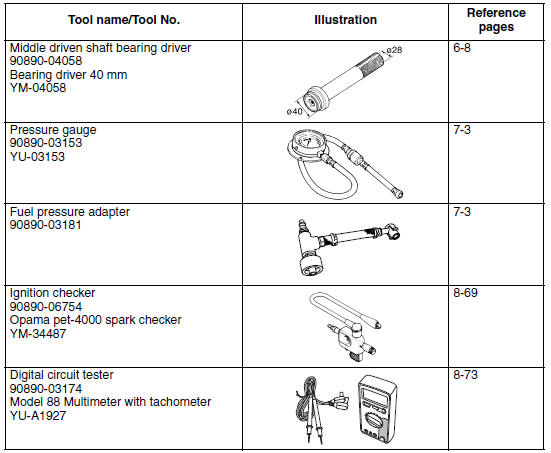

Yamaha YZF-R125 Service Manual: Special tools

The following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools, part numbers or both may differ depending on the country.

When placing an order, refer to the list provided below to avoid any mistakes.

NOTE:

- For U.S.A. and Canada, use part number starting with "YM-", "YU-", or "ACC-".

- For others, use part number starting with "90890-".

Checking the connections

Checking the connections

Check the leads, couplers, and connectors for

stains, rust, moisture, etc.

1. Disconnect:

Lead

Coupler

Connector

2. Check:

Lead

Coupler

Connector

Moisture → Dry with an ...

Specifications

Specifications

General specifications

...

Other materials:

Assembling the crankcase

1. Thoroughly clean all the gasket mating surfaces

and crankcase mating surfaces.

2. Apply:

Sealant

(onto the crankcase mating surfaces)

NOTE:

Do not allow any sealant to come into contact

with the oil gallery.

3. Install:

Right crankcase

NOTE:

Turn the shift drum segment ...

Installing the front brake master cylinder

1. Install:

Brake master cylinder "1"

Brake master cylinder holder "2"

NOTE:

Install the brake master cylinder holder with the

arrow mark "a" pointing forward.

Align the end of the brake master cylinder holder

with the punch mark "b" on the handlebar.

First, tighten the front bo ...

Checking the valve seats

The following procedure applies to all of the

valves and valve seats.

1. Eliminate:

Carbon deposits

(from the valve face and valve seat)

2. Check:

Valve seat

Pitting/wear Replace the

cylinder head.

3. Measure:

Valve seat width C "a"

Out of specification Replace

the ...