Yamaha YZF-R125 Service Manual: Setting the normal mode

NOTE:

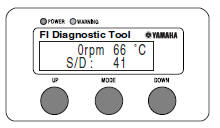

The engine speed, coolant temperature, and fault code, if detected, can be displayed on the LCD of the FI diagnostic tool when the tool is connected to the vehicle and is set to the normal mode.

1. Set the main switch to "OFF" and the engine stop switch to " ".

".

2. Disconnect the self-diagnosis signal connector "1", and then connect the FI diagnostic tool "2" as shown.

3. Set the main switch to "ON" and start the engine.

NOTE:

- The coolant temperature and engine speed appear on the LCD of the FI diagnostic tool.

- "POWER" LED (green) comes on.

- If a malfunction is detected in the system, the "WARNING" LED (orange) comes on.

4. Stop the engine.

NOTE:

If a malfunction is detected in the system, the fault code appears on the

LCD of the FI diagnostic tool

and the "WARNING" LED (orange) comes on.

5. Set the main switch to "OFF" to cancel the normal mode.

6. Disconnect the FI diagnostic tool and connect the self-diagnosis signal connector.

Diagnostic mode

Diagnostic mode

It is possible to monitor the sensor output data or check the activation of

actuators with the FI diagnostic

tool connected to the vehicle and set to the normal mode or the diagnostic

monitoring ...

Setting the diagnostic mode

Setting the diagnostic mode

1. Set the main switch to "OFF" and the engine stop switch to "

".

2. Disconnect the self-diagnosis signal connector "1", and then connect the FI

diagnostic tool "2" as

shown.

3. Disconnect ...

Other materials:

Chain drive

Removing the drive chain

1. Stand the vehicle on a level surface.

WARNINGSecurely support the vehicle so that there

is

no danger of it falling over.

NOTE:

Place the vehicle on a suitable stand so that the

rear wheel is elevated. ...

Checking the spark plug cap

1. Check:

Spark plug cap resistance

Out of specification Replace.

a. Remove the spark plug cap from the spark

plug lead.

b. Connect the pocket tester ( × 1k)

to the

spark plug cap as shown.

c. Measure the spark plug cap resistance. ...

Checking the horn

1. Check:

Horn resistance

Out of specification Replace.

a. Disconnect the horn connectors from the

horn terminals.

b. Connect the pocket tester ( × 1) to the horn

terminals.

Positive tester probe

horn terminal "1"

Negative tester probe

horn terminal "2"

c. Measure t ...