Yamaha YZF-R125 Service Manual: Adjusting the valve clearance

The following procedure applies to all of the valves.

NOTE:

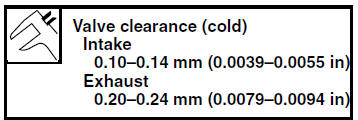

- Valve clearance adjustment should be made on a cold engine, at room temperature.

- When the valve clearance is to be measured or adjusted, the piston must be at top dead center (TDC) on the compression stroke.

1. Remove:

- Bottom cowling Refer to "GENERAL CHASSIS" on page 4-1.

- Fuel tank Refer to "FUEL TANK" on page 7-1.

2. Disconnect:

- Spark plug cap

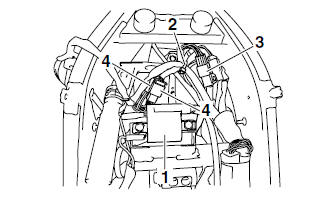

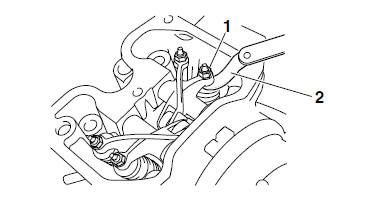

3. Remove:

- Spark plug

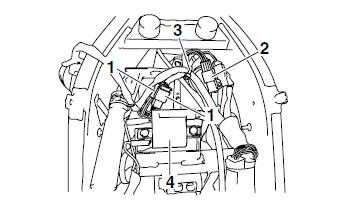

- Ignition coil "1"

- Plastic locking tie "2"

4. Disconnect:

- Main switch coupler "3"

- Left handlebar switch couplers "4"

- Cylinder head cover

- Cylinder head cover gasket Refer to "CYLINDER HEAD" on page 5-7.

NOTE:

When removing the cylinder head cover, lift it out from between the frame tubes.

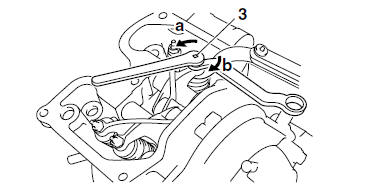

5. Remove:

- Timing mark accessing screw "1"

- Crankshaft end accessing screw "2"

6. Measure:

- Valve clearance

Out of specification → Adjust.

a. Turn the crankshaft counterclockwise.

b. Align the TDC mark "a" on the generator rotor with the stationary pointer "b" on the generator cover.

c. Check that the cam lobes are positioned as shown in the illustration.

d. Measure the valve clearance with a thickness gauge "1".

Out of specification → Adjust.

7. Adjust: - Valve clearance

a. Loosen the locknut "1".

b. Insert a thickness gauge "2" between the end of the adjusting screw and the valve tip.

c. Turn the adjusting screw "3" in direction "a" or "b" until the specified valve clearance is obtained.

- Hold the adjusting screw to prevent it from

moving and tighten the locknut to specification.

d. Measure the valve clearance again.

e. If the valve clearance is still out of specification, repeat all of the valve clearance adjustment steps until the specified clearance is obtained.

8. Install:

- Crankshaft end accessing screw (along with the O-ring

)

) - Timing mark accessing screw

(along with the O-ring

)

)

9. Install:

- Cylinder head cover gasket

- Cylinder head cover

- Spark plug Refer to "CYLINDER HEAD" on page 5-7.

10.Connect:

- Left handlebar switch couplers "1"

- Main switch coupler "2"

11.Install:

- Plastic locking tie "3"

NOTE:

Fasten the wire harness (to horn), wire harness (to left handlebar switch), front brake light switch lead, right handlebar switch lead, and main switch lead to the frame with a plastic locking tie.

Refer to "CABLE ROUTING" on page 2-33.

12.Install:

- Ignition coil "4"

- Spark plug

13.Connect:

- Spark plug cap

14.Install:

- Fuel tank Refer to "FUEL TANK" on page 7-1.

- Bottom cowling Refer to "GENERAL CHASSIS" on page 4-1.

Engine

Engine

...

Adjusting the exhaust gas volume

Adjusting the exhaust gas volume

NOTE:

Be sure to set the CO density level to standard,

and then adjust the exhaust gas volume.

1. Remove:

Rider seat

Refer to "GENERAL CHASSIS" on page 4-1.

2. Set the main switch to "OFF" ...

Other materials:

Removing the swingarm

1. Stand the vehicle on a level surface.

WARNINGSecurely support the vehicle

so that there is

no danger of it falling over.

NOTE:

Place the vehicle on a suitable stand so that the

rear wheel is elevated.

2. Measure:

Swingarm side play

Swingarm vertical movement

a. Me ...

Removing the cylinder head

1. Align:

"I" mark "a" on the generator rotor

(with the stationary pointer "b" on the generator

cover)

a. Turn the crankshaft counterclockwise.

b. When the piston is at TDC on the compression

stroke, align the "I" mark "c" on the camshaft

sprocket with the mark "d" on the

cylinder h ...

Engine oil and oil filter element

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter element

replaced at the intervals specified

in the periodic maintenance and lubrication

chart.

To check the engine oil level

Place the vehicle on a level surface

and hol ...