Yamaha YZF-R125 Service Manual: Removing the cylinder head

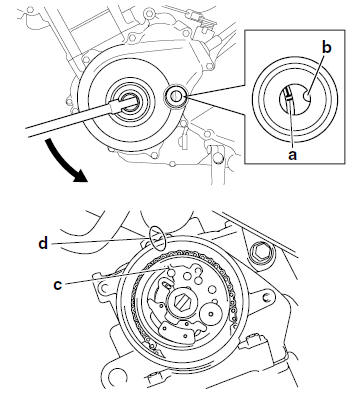

1. Align:

- "I" mark "a" on the generator rotor (with the stationary pointer "b" on the generator cover)

a. Turn the crankshaft counterclockwise.

b. When the piston is at TDC on the compression stroke, align the "I" mark "c" on the camshaft sprocket with the mark "d" on the cylinder head.

2. Loosen:

- Camshaft sprocket bolt "1"

NOTE:

While holding the generator rotor nut with a wrench "2", loosen the camshaft sprocket bolt.

3. Remove:

- Camshaft sprocket

NOTE:

To prevent the timing chain from falling into the crankcase, fasten it with a wire "1".

4. Remove:

- Cylinder head

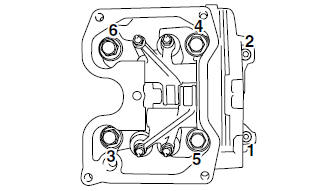

NOTE:

- Loosen the bolts in the proper sequence as shown.

- Loosen each bolt 1/2 of a turn at a time. After all of the bolts are fully loosened, remove bolts 1, 2, 4, and 6, and then remove the cylinder head with bolts 3 and 5 installed in the bolt holes.

Cylinder head

Cylinder head

* Yamaha bond No. 1215 (Three Bond No. 1215) ...

Checking the cylinder head

Checking the cylinder head

1. Eliminate:

Combustion chamber carbon deposits

(with a rounded scraper)

NOTE:

Do not use a sharp instrument to avoid damaging

or scratching:

Spark plug bore threads

Valve seats

...

Other materials:

Checking the condition of the bulbs

The following procedure applies to all of the

bulbs.

1. Remove:

Bulb

WARNINGSince the headlight bulbs get extremely

hot,

keep flammable products and your hands

away from them until they have cooled

down.

CAUTION:

Be sure to hold the socket firmly when re ...

Checking the spark plug

The spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic maintenance

and lubrication chart. In addition,

the condition of the ...

Removing the generator

1. Remove:

Generator rotor nut "1"

Washer

NOTE:

While holding the generator rotor "2" with the

sheave holder "3", loosen the generator rotor

nut.

Do not allow the sheave holder to touch the

projection on the generator rotor.

2. Remove:

Generator rotor "1"

(with the ...