Yamaha YZF-R125 Service Manual: Checking the valve seats

The following procedure applies to all of the valves and valve seats.

1. Eliminate:

- Carbon deposits (from the valve face and valve seat)

2. Check:

- Valve seat

Pitting/wear

Replace the

Replace the

cylinder head.

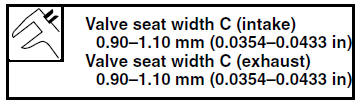

3. Measure:

- Valve seat width C "a"

Out of specification

Replace

Replace

the cylinder head.

a. Apply Mechanic's blueing dye (Dykem) "b" onto the valve face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and onto the valve seat to make a clear impression.

d. Measure the valve seat width.

NOTE:

Where the valve seat and valve face contacted one another, the blueing will have been removed.

4. Lap:

- Valve face

- Valve seat

NOTE:

After replacing the cylinder head or replacing the valve and valve guide, the valve seat and valve face should be lapped.

a. Apply a coarse lapping compound "a" to the valve face.

| CAUTION: Do not let the lapping compound enter the gap between the valve stem and the valve guide. |

b. Apply molybdenum disulfide oil onto the valve stem.

c. Install the valve into the cylinder head.

d. Turn the valve until the valve face and valve seat are evenly polished, then clean off all of the lapping compound.

NOTE:

For the best lapping results, lightly tap the valve seat while rotating the valve back and forth between your hands.

e. Apply a fine lapping compound to the valve face and repeat the above steps.

f. After every lapping procedure, be sure to clean off all of the lapping compound from the valve face and valve seat.

g. Apply Mechanic's blueing dye (Dykem) "b" onto the valve face.

h. Install the valve into the cylinder head.

i. Press the valve through the valve guide and onto the valve seat to make a clear impression.

j. Measure the valve seat width "c" again. If the valve seat width is out of specification, reface and lap the valve seat.

Checking the valves and valve guides

Checking the valves and valve guides

The following procedure applies to all of the

valves and valve guides.

1. Measure:

Valve-stem-to-valve-guide clearance

Out of specification Replace the

valve

guide.

Valve-stem-to-valve ...

Checking the valve springs

Checking the valve springs

The following procedure applies to all of the

valve springs.

1. Measure:

Valve spring free length "a"

Out of specification Replace the valve

spring.

2. Measure:

Compressed valve ...

Other materials:

Assembling the front wheel

1. Install:

Wheel bearings

Oil seal

a. Install the new wheel bearings and oil seal in

the reverse order of disassembly.

CAUTION:Do not contact the wheel bearing inner

race

"1" or balls "2". Contact should be made

only with the outer race "3".

NOTE:

Use a socket " ...

Installing the starter clutch

1. Install:

Starter clutch assembly

Starter clutch bolts "1"

NOTE:

While holding the generator rotor "2" with the

sheave holder "3", tighten the starter clutch

bolts.

Do not allow the sheave holder to touch the

projection on the generator rotor.

Stake the end "a" of each start ...

Checking the starter motor

1. Check:

Commutator

Dirt Clean with 600 grit

sandpaper.

2. Measure:

Commutator diameter "a"

Out of specification Replace

the starter

motor.

3. Measure:

Mica undercut "a"

Out of specification Scrape

the mica to the

proper measurement with a hacksaw blade

...