Yamaha YZF-R125 Service Manual: Checking the valves and valve guides

The following procedure applies to all of the valves and valve guides.

1. Measure:

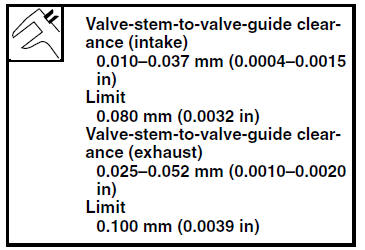

- Valve-stem-to-valve-guide clearance

Out of specification

Replace the

Replace the

valve guide.

Valve-stem-to-valve-guide clearance =

Valve guide inside diameter "a" -

Valve stem diameter "b"

2. Replace:

- Valve guide

NOTE:

To ease valve guide removal and installation, and to maintain the correct fit, heat the cylinder head to 100 C (212 F) in an oven.

a. Remove the valve guide with the valve guide remover "1".

b. Install the new valve guide with the valve

guide installer "2" and valve guide remover

"1".

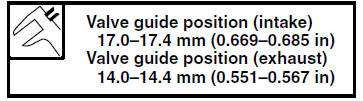

a. Valve guide position

c. After installing the valve guide, bore the valve guide with the valve guide reamer "3" to obtain the proper valve-stem-to-valve-guide clearance.

NOTE:

After replacing the valve guide, reface the valve

seat.

3. Eliminate:

- Carbon deposits (from the valve face and valve seat)

4. Check:

- Valve face

Pitting/wear

Grind the valve

Grind the valve

face. - Valve stem end

Mushroom shape or diameter larger than the

body of the valve stem

Replace

Replace

the valve.

5. Measure:

- Valve margin thickness D "a"

Out of specification

Replace

Replace

the valve.

6. Measure:

- Valve stem runout

Out of specification

Replace

Replace

the valve.

NOTE:

- When installing a new valve, always replace the valve guide.

- If the valve is removed or replaced, always replace

the valve stem seal.

Removing the valves

Removing the valves

The following procedure applies to all of the

valves and related components.

NOTE:

Before removing the internal parts of the cylinder

head (e.g., valves, valve springs, valve seats),

make sure th ...

Checking the valve seats

Checking the valve seats

The following procedure applies to all of the

valves and valve seats.

1. Eliminate:

Carbon deposits

(from the valve face and valve seat)

2. Check:

Valve seat

Pitting/wear Replace the ...

Other materials:

Checking the horn

1. Check:

Horn resistance

Out of specification Replace.

a. Disconnect the horn connectors from the

horn terminals.

b. Connect the pocket tester ( × 1) to the horn

terminals.

Positive tester probe

horn terminal "1"

Negative tester probe

horn terminal "2"

c. Measure t ...

Installing the exhaust assembly

1. Install:

Exhaust assembly "1"

Exhaust pipe nuts "2"

Exhaust assembly bolts "3" "4"

NOTE:

Do not fully tighten the nuts and bolts.

2. Tighten:

Exhaust pipe nuts "2"

Exhaust assembly bolt "4"

Exhaust assembly bolt "3"

...

Installing the rear shock absorber assembly

1. Install:

Rear shock absorber assembly

Relay arm "1"

NOTE:

Install the relay arm as shown in the illustration.

2. Tighten:

Rear shock absorber assembly upper nut

Relay arm nut

Rear shock absorber assembly lower nut

3. Install:

Connecting arms

NOTE:

When ins ...