Yamaha YZF-R125 Service Manual: Changing the engine oil

1. Remove:

- Right bottom cowling

- Right upper side cowling

- Right lower side cowling Refer to "GENERAL CHASSIS" on page 4-1.

2. Start the engine, warm it up for several minutes, and then turn it off.

3. Place a container under the engine oil drain bolt.

4. Install:

- Engine oil drain attachment "1" (Located under the rider seat with the owner's tool kit)

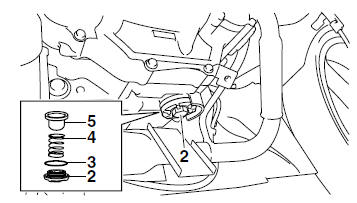

5. Remove:

- Engine oil filler cap (dipstick) "1"

- Engine oil drain plug "2"

- O-ring "3"

- Spring "4"

- Engine oil strainer "5"

6. Drain:

- Engine oil (completely from the crankcase)

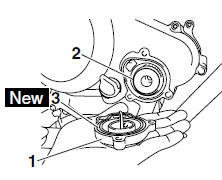

7. If the oil filter element is also to be replaced, perform the following procedure.

a. Remove the oil filter element cover "1" and oil filter element "2".

b. Install the new O-ring "3".

c. Install the new oil filter element and the oil filter

element cover.

8. Check:

- Engine oil strainer

Dirt

Clean.

Clean.

9. Install:

- Engine oil strainer

- Spring

- O-ring

- Engine oil drain plug

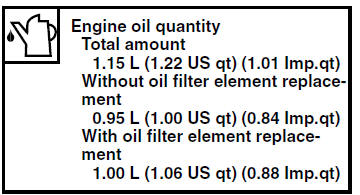

10.Fill:

- Crankcase (with the specified amount of the recommended engine oil)

11.Install:

- Engine oil filler cap

12.Start the engine, warm it up for several minutes, and then turn it off.

13.Check:

- Engine (for engine oil leaks)

14.Check:

- Engine oil level Refer to "CHECKING THE ENGINE OIL LEVEL" on page 3-10.

15.Check:

- Engine oil pressure

a. Slightly loosen the oil check bolt "1".

b. Start the engine and keep it idling until engine oil starts to seep from the oil check bolt. If no engine oil comes out after one minute, turn the engine off so that it will not seize.

c. Check the engine oil passages, the oil filter element and the oil pump for damage or leakage.

Refer to "OIL PUMP" on page 5-47.

d. Start the engine after solving the problem(s) and check the engine oil pressure again.

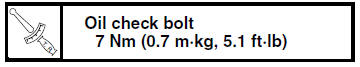

e. Tighten the oil check bolt to specification.

16.Install:

- Right lower side cowling

- Right upper side cowling

- Right bottom side cowling Refer to "GENERAL CHASSIS" on page 4-1.

Checking the engine oil level

Checking the engine oil level

1. Stand the vehicle on a level surface.

NOTE:

Place the vehicle on a suitable stand.

Make sure the vehicle is upright.

2. Start the engine, warm it up for several minutes,

and then turn it ...

Adjusting the clutch cable free play

Adjusting the clutch cable free play

1. Check:

Clutch cable free play "a"

Out of specification Adjust.

2. Adjust:

Clutch cable free play

a. Pull back the rubber cover "1"

b. Loosen the locknut "2".

c. Turn the adjust ...

Other materials:

Engine break-in

There is never a more important period

in the life of your engine than the period

between 0 and 1000 km (600 mi). For

this reason, you should read the following

material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1000 km (600 mi). The vari ...

Checking the cooling system

1. Remove:

Side covers

Upper side cowlings

Refer to "GENERAL CHASSIS" on page 4-1.

2. Check:

Radiator "1"

Radiator inlet hose "2"

Radiator outlet hose "3"

Coolant reservoir hose "4"

Water pump breather hose "5"

Cracks/damage → Replace.

Refer to "RADIATOR" on page 6-1 ...

Installing the valves

The following procedure applies to all of the

valves and related components.

1. Deburr:

Valve stem end

(with an oil stone)

2. Lubricate:

Valve stem "1"

Valve stem seal "2"

(with the recommended lubricant)

3. Install:

Lower spring seat "1"

Valve stem seal "2"

V ...