Yamaha YZF-R125 Service Manual: Air induction system

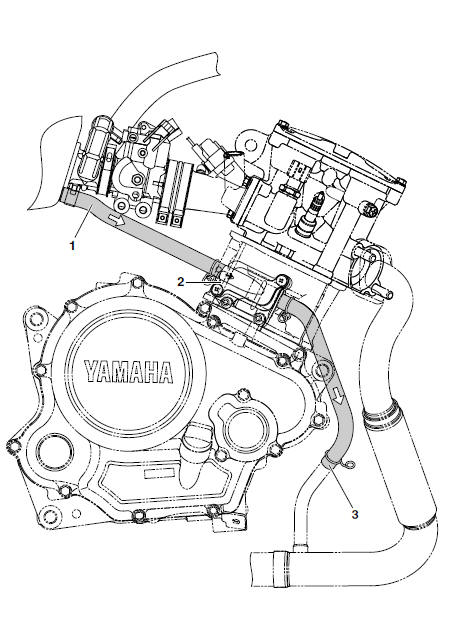

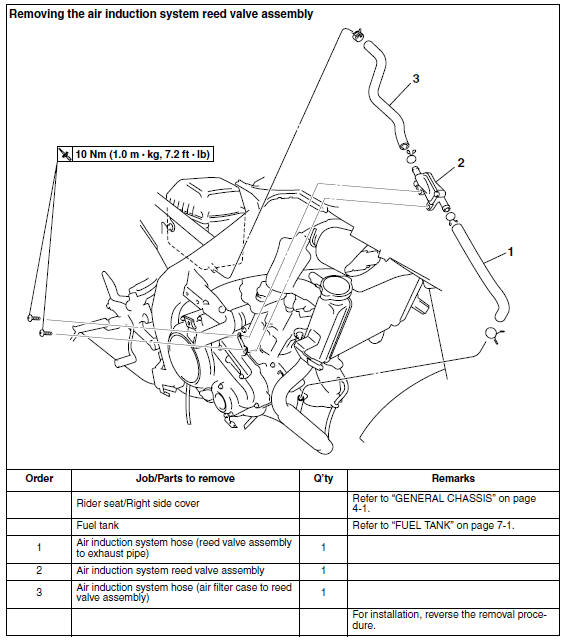

1. Air induction system hose (air filter case to reed valve assembly) 2. Air induction system reed valve assembly

3. Air induction system hose (reed valve assembly to exhaust pipe)

Checking the air induction system

Air injection

The air induction system burns unburned exhaust gases by injecting fresh air (secondary air) into the exhaust port, reducing the emission of hydrocarbons. When there is negative pressure at the exhaust port, the reed valve opens, allowing secondary air to flow into the exhaust port.

The required temperature for burning the unburned exhaust gases is approximately 600 to 700 C (1112 to 1292 F).

1. Check:

- Hoses

Loose connections

Connect

Connect

properly.Cracks/damage

Replace.

Replace. - Cracks/damage

Replace.

Replace.

2. Check:

- Air induction system reed valve assembly operation

a. Blow air into the pipe "1" of the air induction system reed valve assembly and check that it comes out from the pipe "2".

b. Blow air into the pipe "2" of the air induction system reed valve assembly and check that it does not come out from the pipe "1".

c. If faulty, replace the air induction system reed valve assembly.

Installing the throttle body

Installing the throttle body

1. Install:

Throttle body joint clamps

NOTE:

Align the projections "a" on the throttle body joint

with the slot "b" in each throttle body joint clamp.

2. Install:

Throttle body joint ...

Other materials:

Be a Responsible Owner

As the vehicle's owner, you are responsible

for the safe and proper operation

of your motorcycle.

Motorcycles are single-track vehicles.

Their safe use and operation are dependent

upon the use of proper riding

techniques as well as the expertise of

the operator. Every operator should

...

Adjusting the rear disc brake

1. Check:

Brake pedal position

(distance "a" from the center of the rider footrest

to the center of the brake pedal)

Out of specification Adjust.

2. Adjust:

Brake pedal position

a. Loosen the locknut "1".

b. Remove the cotter pin "2", washer "3", and

pin "4".

c. Turn t ...

Introduction

Welcome to the Yamaha world of motorcycling!

As the owner of the YZF-R125, you are benefiting from Yamaha's vast

experience and newest technology regarding the design

and manufacture of high-quality products, which have earned Yamaha a reputation

for dependability.

Please take the time to re ...