Yamaha YZF-R125 Service Manual: Troubleshooting method

The engine operation is not normal and the engine trouble warning light comes on.

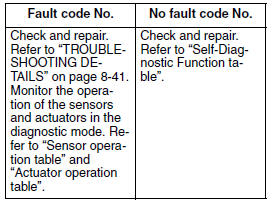

1. Check:

- Fault code number

a. Check the fault code number displayed on the FI diagnostic tool.

b. Identify the faulty system with the fault code.

Refer to "Self-Diagnostic Function table".

c. Identify the probable cause of the malfunction.

Refer to "Diagnostic code table".

2. Check and repair the probable cause of the

malfunction.

3. Perform fuel injection system reinstatement action.

Refer to "Reinstatement method" of table in "TROUBLESHOOTING DETAILS" on page 8-41.

4. Set the main switch to "OFF" and back to "ON", and then check that no fault code number is displayed.

NOTE:

If other fault codes are displayed, repeat steps (1) to (4) until no fault code number is displayed.

5. Erase the malfunction history in the diagnostic mode. Refer to "Sensor operation table (Diagnostic code No. 62)".

NOTE:

Setting the main switch to "OFF" will not erase the malfunction history.

The engine operation is not normal but the engine trouble warning light does not come on.

1. Check the operation of the following sensors

and actuators in the diagnostic mode. Refer

to "Sensor operation table" and "Actuator operation

table".

If a malfunction is detected in the sensors or actuators, repair or replace all faulty parts.

If no malfunction is detected in the sensors and actuators, check and repair the inner parts of the engine.

Self-diagnostic function table

Self-diagnostic function table

If the ECU detects an abnormal signal from a sensor while the vehicle is

being driven, the ECU illuminates

the engine trouble warning light and provides the engine with alternate

operating instru ...

Diagnostic mode

Diagnostic mode

It is possible to monitor the sensor output data or check the activation of

actuators with the FI diagnostic

tool connected to the vehicle and set to the normal mode or the diagnostic

monitoring ...

Other materials:

Ecu self-diagnostic function

The ECU is equipped with a self-diagnostic function in order to ensure that

the fuel injection system is

operating normally. If this function detects a malfunction in the system, it

immediately operates the engine

under substitute characteristics and illuminates the engine trouble warning

li ...

Checking the rear brake caliper

1. Check:

Brake caliper piston "1"

Rust/scratches/wear Replace the

brake

caliper piston.

Brake caliper cylinder "2"

Scratches/wear Replace the

brake caliper

assembly.

Brake caliper body "3"

Cracks/damage Replace the

brake caliper

assembly.

Brake fluid deli ...

Throttle position sensor

1. Check:

Throttle position sensor

a. Connect the digital circuit tester to the terminals

of the throttle body sensor assembly

coupler as shown.

Positive tester probe →

gray/red terminal "1"

Negative tester probe →

gray/black terminal "2"

b. Measure the throttle pos ...