Yamaha YZF-R125 Service Manual: Outline of the fi system

The main function of a fuel supply system is to provide fuel to the combustion chamber at the optimum air-fuel ratio in accordance with the engine operating conditions and the atmospheric temperature. In the conventional carburetor system, the air-fuel ratio of the mixture that is supplied to the combustion chamber is created by the volume of the intake air and the fuel that is metered by the jet used in the respective carburetor.

Despite the same volume of intake air, the fuel volume requirement varies by the engine operating conditions, such as acceleration, deceleration, or operating under a heavy load. Carburetors that meter the fuel through the use of jets have been provided with various auxiliary devices, so that an optimum airfuel ratio can be achieved to accommodate the constant changes in the operating conditions of the engine.

As the requirements for the engine to deliver more performance and cleaner exhaust gases increase, it becomes necessary to control the air-fuel ratio in a more precise and finely tuned manner. To accommodate this need, this model has adopted an electronically controlled fuel injection (FI) system, in place of the conventional carburetor system. This system can achieve an optimum air-fuel ratio required by the engine at all times by using a microprocessor that regulates the fuel injection volume according to the engine operating conditions detected by various sensors.

The adoption of the FI system has resulted in a highly precise fuel supply, improved engine response, better fuel economy, and reduced exhaust emissions.

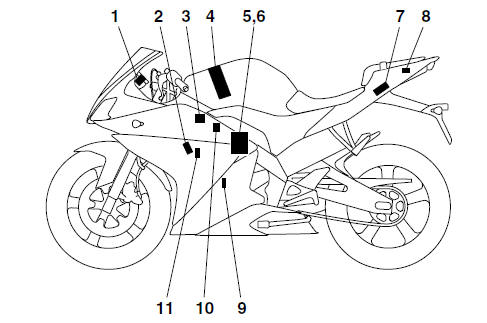

- Engine trouble warning light

- Spark plug

- Ignition coil

- Fuel pump

- FID (fast idle solenoid)

- Throttle body sensor assembly (consisting of throttle position sensor, intake air pressure sensor, intake air temperature sensor)

- ECU (engine control unit)

- Lean angle sensor

- Crankshaft position sensor

- Fuel injector

- Coolant temperature sensor

Features

Features

...

Fi system

Fi system

The fuel pump delivers fuel to the fuel injector via the fuel filter. The

pressure regulator maintains the

fuel pressure that is applied to the fuel injector at only 250 kPa (2.50 kg/cm²,

36 ...

Other materials:

Installing the camshaft and rocker arms

1. Lubricate:

Rocker arms

Rocker arm shafts

2. Lubricate:

Camshaft

3. Install:

Camshaft "1"

NOTE:

Make sure that the camshaft projections "a" and

hole "b" are positioned as shown in the illustration.

4. Install:

Rocker arms

Rocker arm shafts "1"

NOTE:

Make ...

Replacing the fuses

Replacing the fuses

Fuse box

Spare fuse

Headlight fuse

Signaling system fuse

Ignition fuse

Radiator fan fuse

Main fuse

The fuse box is located under the rider

seat.

If a fuse is blown, replace it as follows.

Turn the key to "OFF" and turn off

the electrical circuit i ...

Unstable handling

Handlebars

- Bent or improperly installed right handlebar

- Bent or improperly installed left handlebar

1. Steering head components

- Improperly installed upper bracket

- Improperly installed lower bracket

(improperly tightened ring nut)

- Bent steering stem

- Damaged ball bearing or bearing ...