Yamaha YZF-R125 Service Manual: Installing the rear brake master cylinder

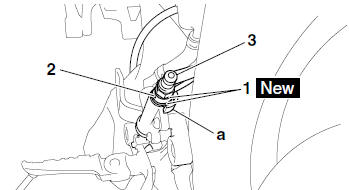

1. Install:

- Copper washers "1"

- Brake hose "2"

- Rear brake light switch "3"

| WARNING Proper brake hose routing is essential to insure safe vehicle operation. Refer to "CABLE ROUTING" on page 2-33. |

| CAUTION: When installing the brake hose onto the brake master cylinder, make sure the brake pipe touches the projection "a" as shown. |

2. Fill:

- Brake fluid reservoir

(with the specified amount of the recommended

brake fluid)

WARNING

|

| CAUTION: Brake fluid may damage painted surfaces and plastic parts. Therefore, always clean up any spilt brake fluid immediately. |

3. Bleed:

- Brake system Refer to "BLEEDING THE HYDRAULIC BRAKE SYSTEM" on page 3-20.

4. Check:

- Brake fluid level

Below the minimum level mark "a"

Add the recommended brake fluid to the proper level.Refer to "CHECKING THE BRAKE FLUID LEVEL" on page 3-18.

5. Check:

- Brake pedal operation

Soft or spongy feeling

Bleed

Bleed

the brake system.Refer to "BLEEDING THE HYDRAULIC BRAKE SYSTEM" on page 3-20.

6. Adjust:

- Brake pedal position

Refer to "ADJUSTING THE REAR DISC

BRAKE" on page 3-18.

Assembling the rear brake master cylinder

Assembling the rear brake master cylinder

WARNING

Before installation, all internal brake components

should be cleaned and lubricated

with clean or new brake fluid.

Never use solvents on internal brake components.

...

Handlebars

Handlebars

...

Other materials:

Checking the shift drum assembly

1. Check:

Shift drum groove

Damage/scratches/wear Replace

the shift

drum assembly.

Shift drum segment "1"

Damage/wear Replace the

shift drum assembly.

Shift drum bearing "2"

Damage/pitting Replace the

shift drum assembly.

...

Checking the transmission

1. Measure:

Main axle runout

(with a centering device and dial gauge "1")

Out of specification Replace

the main axle.

2. Measure:

Drive axle runout

(with a centering device and dial gauge "1")

Out of specification Replace

the drive axle.

3. Check:

Transmiss ...

Removing the crankshaft

1. Remove:

Crankshaft "1"

NOTE:

Remove the crankshaft with the crankcase

separating tool "2".

Make sure the crankcase separating tool is

centered over the crankshaft.

CAUTION:

To protect the end of the crankshaft, place

an appropriate sized socket between the

c ...