Yamaha YZF-R125 Service Manual: Checking the valve seats

The following procedure applies to all of the valves and valve seats.

1. Eliminate:

- Carbon deposits (from the valve face and valve seat)

2. Check:

- Valve seat

Pitting/wear

Replace the

Replace the

cylinder head.

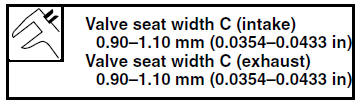

3. Measure:

- Valve seat width C "a"

Out of specification

Replace

Replace

the cylinder head.

a. Apply Mechanic's blueing dye (Dykem) "b" onto the valve face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and onto the valve seat to make a clear impression.

d. Measure the valve seat width.

NOTE:

Where the valve seat and valve face contacted one another, the blueing will have been removed.

4. Lap:

- Valve face

- Valve seat

NOTE:

After replacing the cylinder head or replacing the valve and valve guide, the valve seat and valve face should be lapped.

a. Apply a coarse lapping compound "a" to the valve face.

| CAUTION: Do not let the lapping compound enter the gap between the valve stem and the valve guide. |

b. Apply molybdenum disulfide oil onto the valve stem.

c. Install the valve into the cylinder head.

d. Turn the valve until the valve face and valve seat are evenly polished, then clean off all of the lapping compound.

NOTE:

For the best lapping results, lightly tap the valve seat while rotating the valve back and forth between your hands.

e. Apply a fine lapping compound to the valve face and repeat the above steps.

f. After every lapping procedure, be sure to clean off all of the lapping compound from the valve face and valve seat.

g. Apply Mechanic's blueing dye (Dykem) "b" onto the valve face.

h. Install the valve into the cylinder head.

i. Press the valve through the valve guide and onto the valve seat to make a clear impression.

j. Measure the valve seat width "c" again. If the valve seat width is out of specification, reface and lap the valve seat.

Checking the valves and valve guides

Checking the valves and valve guides

The following procedure applies to all of the

valves and valve guides.

1. Measure:

Valve-stem-to-valve-guide clearance

Out of specification Replace the

valve

guide.

Valve-stem-to-valve ...

Checking the valve springs

Checking the valve springs

The following procedure applies to all of the

valve springs.

1. Measure:

Valve spring free length "a"

Out of specification Replace the valve

spring.

2. Measure:

Compressed valve ...

Other materials:

Engine oil and oil filter element

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter element

replaced at the intervals specified

in the periodic maintenance and lubrication

chart.

To check the engine oil level

Place the vehicle on a level surface

and hol ...

Clutch lever

Clutch lever

Clutch lever

The clutch lever is located at the left

handlebar grip. To disengage the

clutch, pull the lever toward the handlebar

grip. To engage the clutch, release

the lever. The lever should be pulled

rapidly and released slowly for smooth

clutch operation.

Th ...

Removing the crankshaft

1. Remove:

Crankshaft "1"

NOTE:

Remove the crankshaft with the crankcase

separating tool "2".

Make sure the crankcase separating tool is

centered over the crankshaft.

CAUTION:

To protect the end of the crankshaft, place

an appropriate sized socket between the

c ...