Yamaha YZF-R125 Service Manual: Assembling the front fork legs

The following procedure applies to both of the front fork legs.

WARNING

|

NOTE:

When assembling the front fork leg, be sure to replace the following parts:

- Outer tube bushing

- Oil seal

- Dust seal

- Clip

Before assembling the front fork leg, make sure all of the components are clean.

1. Install:

- Damper rod

| CAUTION: Allow the damper rod to slide slowly down the inner tube until it protrudes from the bottom of the inner tube. Be careful not to damage the inner tube. |

2. Lubricate:

- Inner tube's outer surface

3. Tighten:

- Damper rod bolt "1"

NOTE:

While holding the damper rod with the damper

rod holder "2" and T-handle "3", tighten the

damper rod bolt.

4. Install:

- Outer tube bushing "1"

- Washer "2"

(with the fork seal driver weight "3" and fork

seal driver attachment "4")

5. Install:

- Oil seal "1"

(with the fork seal driver weight "2" and fork seal driver attachment "3")

| CAUTION: Make sure the numbered side of the oil seal faces up. |

NOTE:

- Before installing the oil seal, lubricate its lips with lithium-soap-based grease.

- Lubricate the outer surface of the inner tube with fork oil.

- Before installing the oil seal, cover the top of

the front fork leg with a plastic bag to protect

the oil seal during installation.

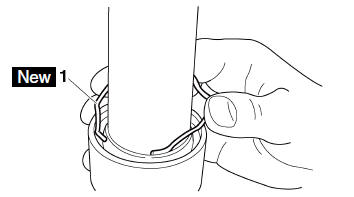

6. Install:

- Oil seal clip "1"

NOTE:

Adjust the oil seal clip so that it fits into the outer tube's groove.

7. Install:

- Dust seal "1"

(with the fork seal driver weight "2")

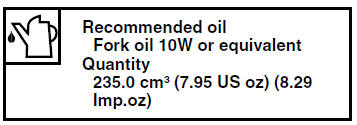

8. Fill:

- Front fork leg

(with the specified amount of the recommended

fork oil)

CAUTION:

|

9. After filling the front fork leg, slowly stroke the inner tube "1" up and down (at least ten times) to distribute the fork oil.

NOTE:

Be sure to stroke the inner tube slowly because the fork oil may spurt out.

10.Before measuring the fork oil level, wait ten minutes until the oil has settled and the air bubbles have dispersed.

NOTE:

Be sure to bleed the front fork leg of any residual air.

11.Measure:

Front fork leg oil level "a"

(from the top of the inner tube, with the inner

tube fully compressed and without the fork

spring)

Out of specification  Correct.

Correct.

12.Install:

12.Install:

- Fork spring "1"

NOTE:

Install the spring with the smaller pitch "a" facing

up.

13.Install:

- O-ring

(to front fork cap) - Front fork cap

- Clip

NOTE:

- Before installing the front fork cap, lubricate its O-ring with grease.

- Insert the front fork cap into the inner tube, and then install the clip, making sure that the cap is securely held in place with the clip.

Checking the front fork legs

Checking the front fork legs

The following procedure applies to both of the

front fork legs.

1. Check:

Inner tube

Outer tube

Bends/damage/scratches

Replace.

WARNINGDo not attempt to straighten a bent inner ...

Installing the front fork legs

Installing the front fork legs

The following procedure applies to both of the

front fork legs.

1. Install:

Front fork leg

Temporarily tighten the upper and lower

bracket pinch bolts.

NOTE:

Make sure the inner tube end ...

Other materials:

Checking the speed sensor

1. Check:

Speed sensor output voltage

Out of specification → Replace.

a. Connect the pocket tester (DC 20 V) to the

speed sensor coupler (wire harness end) as

shown.

Positive tester probe

gray "1"

Negative tester probe

gray/black "2"

b. Set the main switch to "ON".

c. ...

Periodic maintenance and adjustment

Periodic inspection, adjustment, and lubrication

will keep your vehicle in the

safest and most efficient condition possible.

Safety is an obligation of the vehicle

owner/operator. The most important

points of vehicle inspection, adjustment,

and lubrication are explained on

the followin ...

Checking the rear brake disc

1. Remove:

Rear wheel

Refer to "REAR WHEEL" on page 4-12.

2. Check:

Brake disc

Damage/galling → Replace.

3. Measure:

Brake disc deflection

Out of specification → Correct the brake

disc

deflection or replace the brake disc.

Refer to "CHECKING THE FRONT BRAKE

DIS ...