Yamaha YZF-R125 Service Manual: Measuring the compression pressure

NOTE:

Insufficient compression pressure will result in a loss of performance.

1. Measure:

Valve clearance Out of specification →Adjust.

Refer to "ADJUSTING THE VALVE CLEARANCE" on page 3-3.

2. Start the engine, warm it up for several minutes, and then turn it off.

3. Remove:

- Rider seat

- Right upper side cowling Refer to "GENERAL CHASSIS" on page 4-1.

4. Remove:

- Fuel tank Refer to "FUEL TANK" on page 7-1.

5. Disconnect:

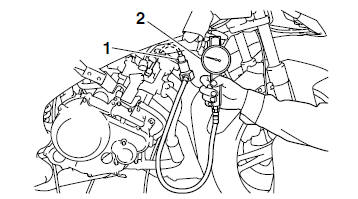

- Coolant temperature sensor coupler "1"

- Spark plug cap "2"

6. Remove:

- Spark plug

| CAUTION: Before removing the spark plug, use compressed air to blow away any dirt accumulated in the spark plug well to prevent it from falling into the cylinder. |

7. Install:

- Extension "1"

- Compression gauge "2"

8. Measure:

- Compression pressure

Out of specification Refer to steps (c) and

(d).

a. Set the main switch to "ON".

b. With the throttle wide open, crank the engine until the reading on the compression gauge stabilizes.

c. If the compression pressure is above the maximum specification, check the cylinder head, valve surfaces and piston crown for carbon deposits.

Carbon deposits Eliminate.

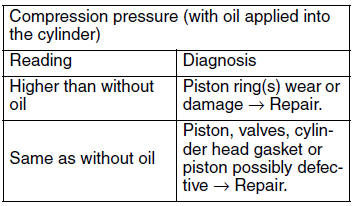

d. If the compression pressure is below the minimum specification, pour a teaspoonful of engine oil into the spark plug bore and measure again.

Refer to the following table.

9. Remove:

- Extension

- Compression gauge

10.Install:

- Spark plug

11.Connect:

- Spark plug cap

- Coolant temperature sensor coupler

12.Install:

- Fuel tank Refer to "FUEL TANK" on page 7-1.

13.Install:

- Right upper side cowling

- Rider seat Refer to "GENERAL CHASSIS" on page 4-1.

Checking the ignition timing

Checking the ignition timing

NOTE:

Prior to checking the ignition timing, check the

wiring connections of the entire ignition system.

Make sure all connections are tight and free of

corrosion.

1. Remove:

Rider seat

L ...

Checking the engine oil level

Checking the engine oil level

1. Stand the vehicle on a level surface.

NOTE:

Place the vehicle on a suitable stand.

Make sure the vehicle is upright.

2. Start the engine, warm it up for several minutes,

and then turn it ...

Other materials:

Protective apparel

The majority of fatalities from motorcycle

accidents are the result of head injuries.

The use of a safety helmet is the

single most critical factor in the prevention

or reduction of head injuries.

Always wear an approved helmet.

Wear a face shield or goggles.

Wind in your unprotecte ...

Checking and lubricating the cables

The operation of all control cables and

the condition of the cables should be

checked before each ride, and the cables

and cable ends should be lubricated

if necessary. If a cable is damaged

or does not move smoothly, have a

Yamaha dealer check or replace it.

WARNING! Damage to the out ...

Installing the camshaft and rocker arms

1. Lubricate:

Rocker arms

Rocker arm shafts

2. Lubricate:

Camshaft

3. Install:

Camshaft "1"

NOTE:

Make sure that the camshaft projections "a" and

hole "b" are positioned as shown in the illustration.

4. Install:

Rocker arms

Rocker arm shafts "1"

NOTE:

Make ...