Yamaha YZF-R125 Service Manual: Ecu self-diagnostic function

The ECU is equipped with a self-diagnostic function in order to ensure that the fuel injection system is operating normally. If this function detects a malfunction in the system, it immediately operates the engine under substitute characteristics and illuminates the engine trouble warning light to alert the rider that a malfunction has occurred in the system. Once a malfunction has been detected, a fault code is stored in the memory of the ECU.

- To inform the rider that the fuel injection system is not functioning, the engine trouble warning light flashes when the start switch is being pushed to start the engine.

- If a malfunction is detected in the system by the self-diagnostic function, the ECU provides an appropriate substitute characteristic operation, and alerts the rider of the detected malfunction by illuminating the engine trouble warning light.

- After the engine has been stopped, the lowest fault code number is

indicated by the engine trouble

warning light (or displayed on the FI diagnostic tool). It remains stored in

the memory of the ECU until

it is deleted.

1. Engine trouble warning light

Engine trouble warning light fault code indication

Digit of 10: Cycles of 1 sec. on and 1.5 sec. off.

Digit of 1: Cycles of 0.5 sec. on and 0.5 sec. off.

Example: 42

a. Light on

b. Light off

c. 1

d. 1.5

e. 0.5

f. 3

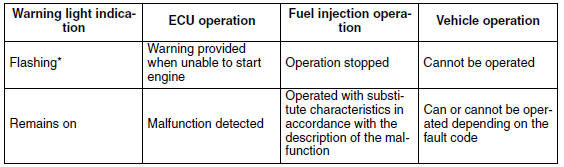

Engine trouble warning light indication and fuel injection system

operation

* The warning light flashes when any one of the conditions listed below is present and the start switch is pushed:

19: Blue/yellow ECU lead (broken or disconnected)

30: Lean angle sensor (latch up detected)

33: Faulty ignition

39: Fuel injector (open or short circuit)

41: Lean angle sensor (open or short circuit)

50: ECU internal malfunction (memory check error)

Checking the engine trouble warning light

The engine trouble warning light comes on for 3 seconds after the main switch

has been set to "ON". If

the warning light does not come on under these conditions, the warning light

(LED) may be defective.

a. Main switch "OFF"

b. Main switch "ON"

c. Engine trouble warning light off

d. Engine trouble warning light on for 3 seconds

Circuit diagram

Circuit diagram

2. Crankshaft position sensor

4. Main fuse

5. Main switch

6. Radiator fan motor fuse

8. Sidestand switch

9. Battery

17.Engine stop switch

19.Intake air pressure sensor

20.Intake air temper ...

Self-diagnostic function table

Self-diagnostic function table

If the ECU detects an abnormal signal from a sensor while the vehicle is

being driven, the ECU illuminates

the engine trouble warning light and provides the engine with alternate

operating instru ...

Other materials:

Lubricating the drive chain

The drive chain consists of many interacting

parts. If the drive chain is not maintained properly,

it will wear out quickly. Therefore, the drive

chain should be serviced, especially when the

vehicle is used in dusty areas.

This vehicle has a drive chain with small rubber

O-rings between eac ...

Checking and replacing the rear wheel sprocket

1. Check:

Rear wheel sprocket

More than 1/4 tooth "a" wear

Replace the

rear wheel sprocket.

Bent teeth Replace the rear

wheel sprocket.

b. Correct

1. Drive chain roller

2. Rear wheel sprocket

2. Replace:

Rear wheel sprocket

a. Remove the self-locking nuts and the ...

Checking the radiator

1. Check:

Radiator fins

obstruction clean.

Apply compressed air to the rear of the radiator.

Damage repair or replace.

NOTE:

Straighten any flattened fins with a thin, flat-head

screwdriver.

2. Check:

Radiator hoses

Cracks/damage Replace.

3. Measure:

Radiator cap ...