Yamaha YZF-R125 Owners Manual: Drive chain slack

The drive chain slack should be checked before each ride and adjusted if necessary.

To check the drive chain slack

- Place the motorcycle on the sidestand.

TIP

When checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.

- Shift the transmission into the neutral position.

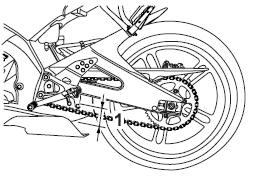

- Move the rear wheel by pushing the motorcycle to locate the tightest portion of the drive chain, and then measure the drive chain slack as shown.

| Drive chain slack: 30.0-40.0 mm (1.18-1.57 in) |

-

Drive chain slack

- If the drive chain slack is incorrect, adjust it as follows.

To adjust the drive chain slack

- Loosen the axle nut and the locknut on each side of the swingarm.

-

Axle nut

-

Drive chain slack adjusting bolt

-

Locknut

-

Alignment marks

- To tighten the drive chain, turn the drive chain slack adjusting bolt on each side of the swingarm in direction (a). To loosen the drive chain, turn the adjusting bolt on each side of the swingarm in direction (b), and then push the rear wheel forward. NOTICE: Improper drive chain slack will overload the engine as well as other vital parts of the motorcycle and can lead to chain slippage or breakage. To prevent this from occurring, keep the drive chain slack within the specified limits.

TIP

Using the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

- Tighten the axle nut, then the locknuts to their specified torques.

| Tightening torques: Axle nut: 85 Nm (8.5 m.kgf, 61 ft.lbf) Locknut: 16 Nm (1.6 m.kgf, 11 ft.lbf) |

Changing the brake fluid

Changing the brake fluid

Have a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrication

chart. In addition, have the brake

hose replaced every four years or

whenev ...

Cleaning and lubricating the drive chain

Cleaning and lubricating the drive chain

The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrication

chart, otherwise it will quickly wear

out, especially when riding in dusty ...

Other materials:

Removing the primary drive gear and balancer gears

1. Loosen:

Primary drive gear nut "1"

NOTE:

Place the aluminum plate "a" between the balancer

drive gear "2" and the balancer driven

gear "3", and then loosen the primary drive gear

nut.

2. Straighten the lock washer tab.

3. Loosen:

Balancer driven gear nut "1"

NOTE:

Place ...

Replacing the air filter element and cleaning the check hose

The air filter element should be replaced

at the intervals specified in the

periodic maintenance and lubrication

chart. Have a Yamaha dealer replace

the air filter element more frequently if

you are riding in unusually wet or dusty

areas. In addition, the air filter check

hose must be ...

Checking and charging the battery

WARNINGBatteries generate explosive hydrogen gas

and contain electrolyte which is made of poisonous

and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

Wear protective eye gear when handling or

working near batteries.

Charge batt ...