Yamaha YZF-R125 Owners Manual: Rear wheel

To remove the rear wheel

WARNING

WARNING

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.

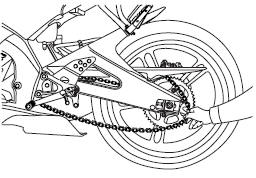

- Loosen the axle nut.

-

Axle nut

-

Drive chain slack adjusting bolt

-

Locknut

-

Brake caliper

- Lift the rear wheel off the ground according to the procedure.

- Remove the axle nut.

- Loosen the locknut on each side of the swingarm.

- Turn the drive chain slack adjusting bolts fully in direction (a) and push the wheel forward.

- Remove the drive chain from the rear sprocket.

TIP

If the drive chain is difficult to remove,

remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

The drive chain cannot be disassembled.

- While supporting the brake caliper bracket, pull the wheel axle out, and then remove the wheel. NOTICE: Do not apply the brake after the wheel has been removed together with the brake disc, otherwise the brake pads will be forced shut.

To install the rear wheel

- Install the wheel and the brake caliper bracket by inserting the wheel axle from the left-hand side.

TIP

- Make sure that the slot in the brake caliper bracket is fit over the retainer on the swingarm.

- Make sure that there is enough space between the brake pads before installing the wheel.

-

Retainer

-

Slot

- Install the drive chain onto the rear sprocket.

- Install the axle nut.

- Lower the rear wheel so that it is on the ground, and then put the sidestand down.

- Adjust the drive chain slack.

- Tighten the axle nut to the specified torque.

| Tightening torque: Axle nut: 85 Nm (8.5 m.kgf, 61 ft.lbf) |

Front wheel

Front wheel

To remove the front wheel

WARNING

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.

Loosen the front wheel axle pinch

bolt, then the wheel axle and ...

Troubleshooting

Troubleshooting

Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur during

operation. Any problem in the fuel,

compression, or ignition systems, for

...

Other materials:

Storage

Short-term

Always store your motorcycle in a cool,

dry place and, if necessary, protect it

against dust with a porous cover.

NOTICE

Storing the motorcycle in a

poorly ventilated room or covering

it with a tarp, while it is still

wet, will allow water and humidity

to seep in and ...

Removing the fuel tank

1. Extract the fuel in the fuel tank through the

fuel tank filler hole with a pump.

2. Remove:

Fuel hose connector cover "1"

3. Disconnect:

Fuel hose "2"

CAUTION:

Be sure to disconnect the fuel hose by

hand. Do not forcefully disconnect the

hose with tools.

A ...

Checking the piston rings

1. Measure:

Piston ring side clearance

Out of specification Replace the

piston

and piston rings as a set.

NOTE:

Before measuring the piston ring side clearance,

eliminate any carbon deposits from the piston

ring grooves and piston rings.

2. Install:

Piston ring

(into the cylind ...