Yamaha YZF-R125 Service Manual: Setting the diagnostic mode

1. Set the main switch to "OFF" and the engine stop switch to "

".

".

2. Disconnect the self-diagnosis signal connector "1", and then connect the FI diagnostic tool "2" as shown.

3. Disconnect the fuel pump coupler.

4. While pressing the "MODE" button, set the main switch to "ON".

NOTE:

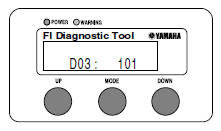

- "DIAG" appears on the LCD of the FI diagnostic tool.

- "POWER" LED (Green) comes on.

5. Press the "UP" button to select the CO adjustment mode "CO" or the diagnostic mode "DIAG".

6. After selecting "DIAG", press the "MODE" button.

7. Select the diagnostic code number corresponding to the fault code number by pressing the "UP" and "DOWN" buttons.

NOTE:

- The diagnostic code number appears on the LCD (01-70).

- To decrease the selected diagnostic code number, press the "DOWN" button. Press the "DOWN" button for 1 second or longer to automatically decrease the diagnostic code numbers.

- To increase the selected diagnostic code number, press the "UP" button. Press the "UP" button for 1 second or longer to automatically increase the diagnostic code numbers.

8. Verify the operation of the sensor or actuator.

- Sensor operation The data representing the operating conditions of the sensor appear on the LCD.

- Actuator operation

Press the "MODE" button.

9. Set the main switch to "OFF" to cancel the diagnostic mode.

10.Disconnect the FI diagnostic tool and connect the self-diagnosis signal connector.

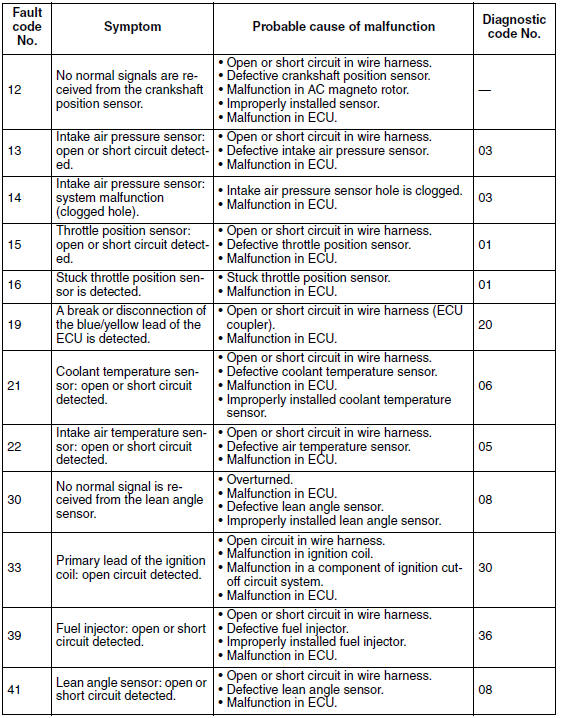

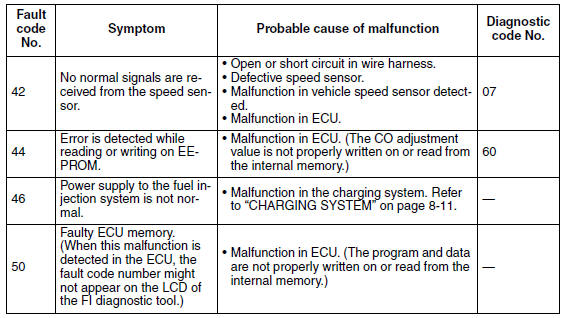

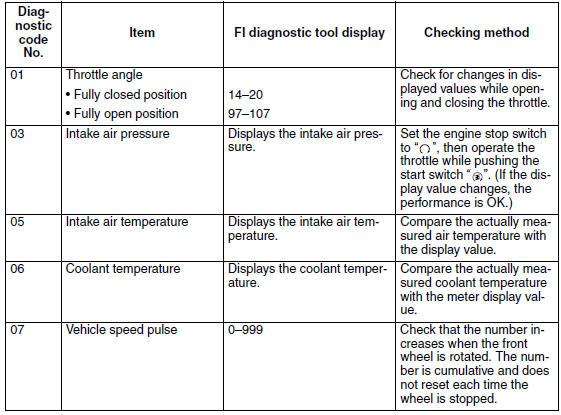

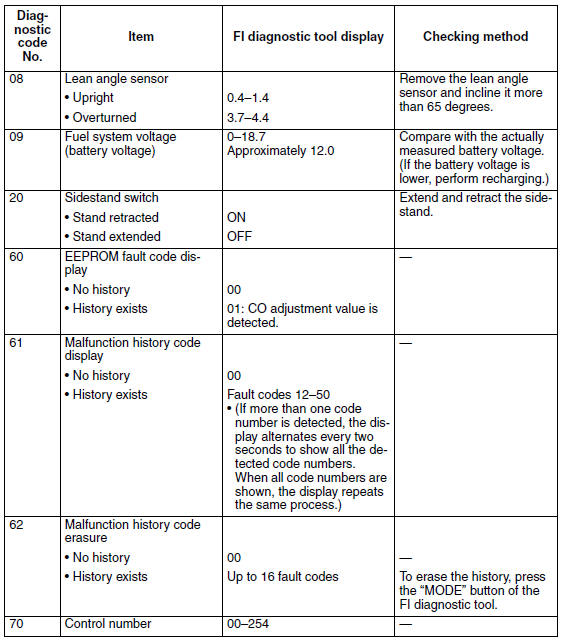

Diagnostic code table

Sensor operation table

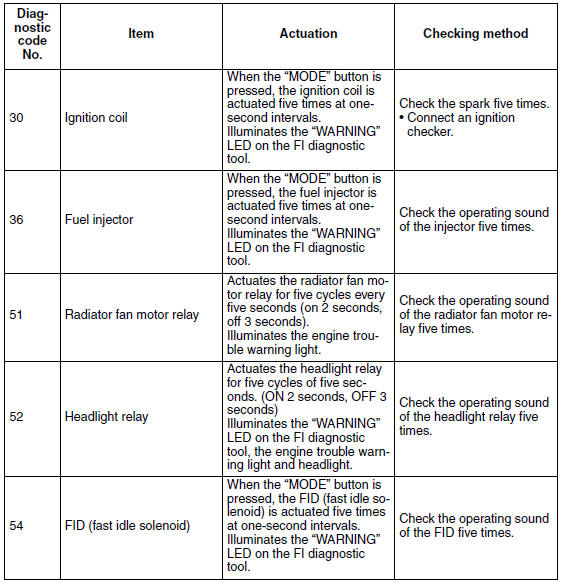

Actuator operation table

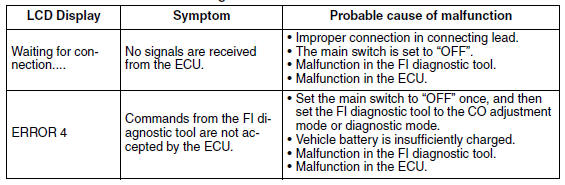

Communication error with the FI diagnostic tool

Setting the normal mode

Setting the normal mode

NOTE:

The engine speed, coolant temperature, and fault code, if detected, can be

displayed on the LCD of the

FI diagnostic tool when the tool is connected to the vehicle and is set to the

normal ...

Troubleshooting details

Troubleshooting details

This section describes the measures per fault code number displayed on the FI

diagnostic tool. Check

and service the items or components that are the probable cause of the

malfunction following t ...

Other materials:

Adjusting the throttle cable free play

NOTE:

Prior to adjusting the throttle cable free play, the

engine idling speed should be adjusted.

1. Check:

Throttle cable free play "a"

Out of specification →Adjust.

2. Remove:

Right side panel

Refer to "GENERAL CHASSIS" on page 4-1.

3. Adjust:

Throttle cable f ...

Adjusting the brake pedal free play

Adjusting the brake pedal free play

Brake pedal free play

The brake pedal free play should measure

3.5-4.5 mm (0.14-0.18 in) as

shown. Periodically check the brake

pedal free play and, if necessary, have

a Yamaha dealer adjust it.

WARNING

An incorrect brake pedal free play

in ...

Starting circuit cut-off system operation

If the engine stop switch is set to "

" and the main switch is set to

"ON" (both switches are closed), the

starter motor can only operate if at least one of the following conditions is

met:

The transmission is in neutral (the neutral switch is closed).

The clutch lever is pulled to the ...